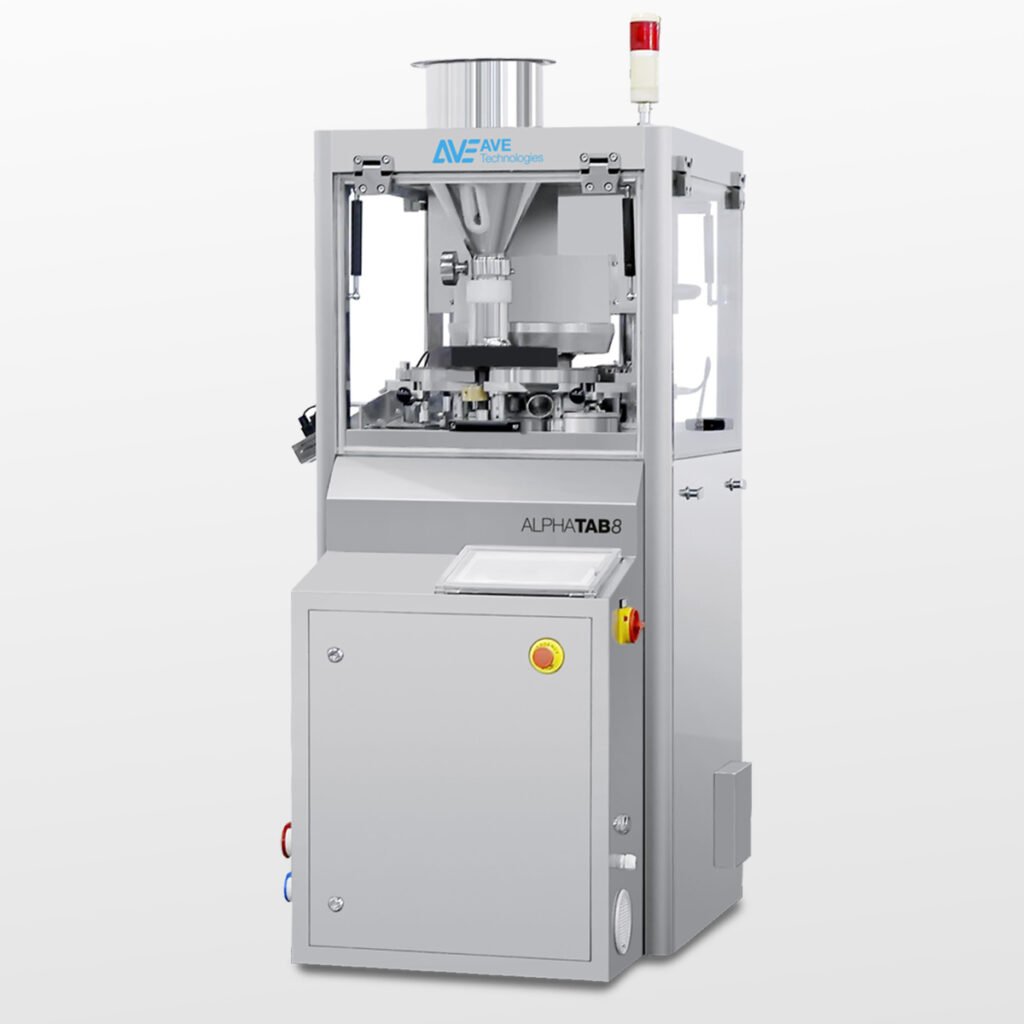

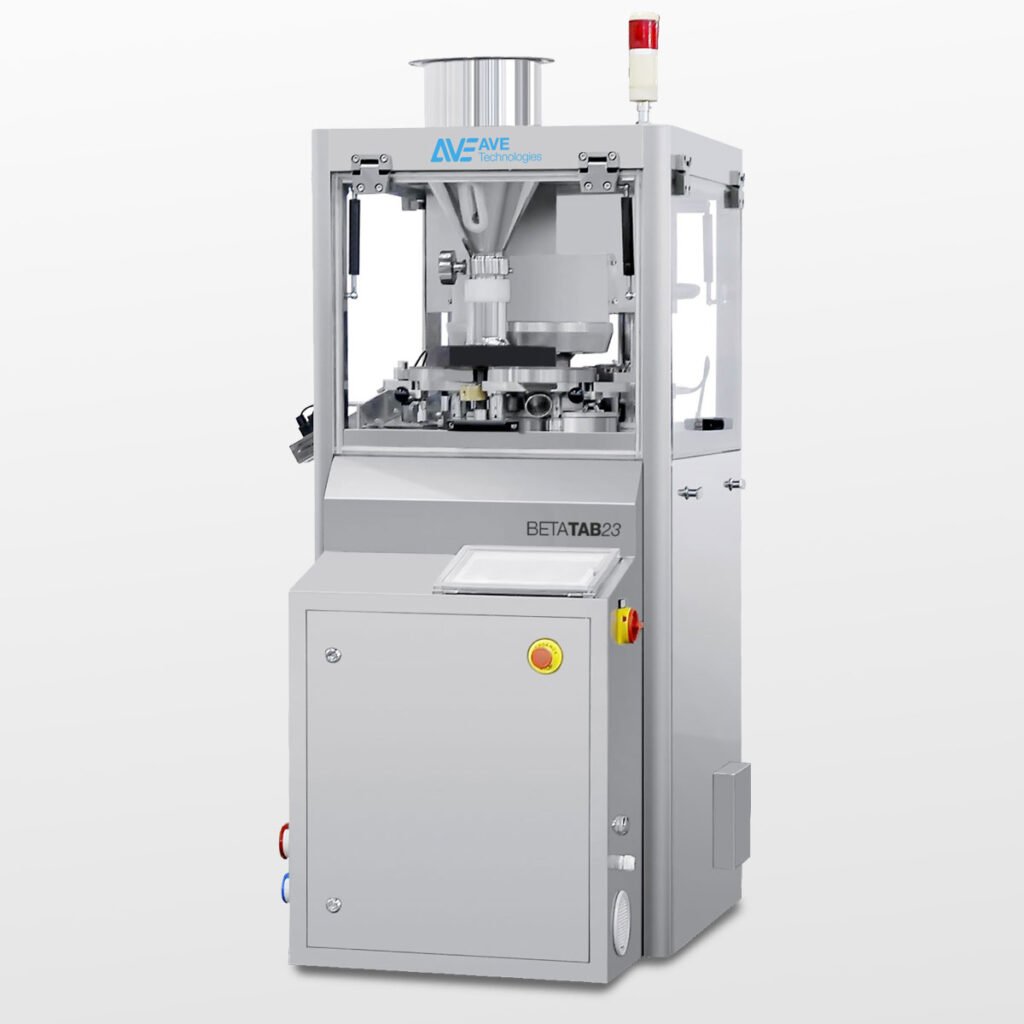

Rotary Tablet Press

ALPHATAB 4+4 Combi / 8

Tablets/hour max: 26,400 – 52,800

Tablet dia max: 16 – 25mm

ALPHATAB Tablet Presses from AVE Technologies are based upon a proven design and is an ideal machine for R&D as well as small scale production. This is due to its robust construction and durability, having a maximum compression force of 100kN and fitted with pre-compression and a rotary force feeder. They are manufactured to the highest standards and compliant with current GMP and CE standards.

Available in two turret sizes giving an output of up to 52,800 tablets per hour (depending upon turret and tooling size).

PLC Control

ALPHATAB machines feature a fully automatic control system together with a user-friendly touch screen HMI, making them machines very easy to operate. They use an industrial PLC and all CE standard components to control the entire tablet press.

The HMI can be mounted on the machine front or in a mobile stand allowing the operator full flexibility to operate the press and providing a platform for optional data output and printing devices.

Operator Access

ALPHATAB has four large top-hinged doors allowing easy access to all areas of the compression zone which also means easier cleaning and maintenance.

Compact Design

ALPHATAB is one of the smallest rotary tablet presses of its type, requiring minimal space and easy installation.

- Easy to maintain and operate

- Industrial PLC controls

- Hard chromium plated die table

- Pre-compression station

- Upper & Lower punch dust seals

- Adjustments are displayed on the operator HMI

- Batch counters and control